Magnetostrictive Sensors Explained: How They Work & Why Industry Can’t Get Enough of Them

- noel pace

- 12 hours ago

- 3 min read

Imagine a sensor so precise that it can detect position within microns — without ever making contact. That’s not science fiction. It’s the power of magnetostrictive sensors, and they’re quietly transforming industries from automation to aerospace.

In this post, we’ll break down how these sensors work, why they’re so valuable, where they’re used, and how to choose the best one.

Bonus: we’ll also link the top magnetostrictive sensors you can buy today.

🔍 What Is a Magnetostrictive Sensor?

A magnetostrictive sensor is a non-contact position sensor that measures linear displacement using the physical properties of magnetostrictive materials — materials that change shape when exposed to a magnetic field.

In simple terms: It measures position using a wave and a magnet, with no moving parts touching.

⚙️ How Do Magnetostrictive Sensors Work?

Here’s a simplified breakdown:

A magnet is attached to the moving part of a machine.

Inside the sensor, a magnetostrictive waveguide is fixed in place.

The sensor sends a current pulse down the waveguide.

When the pulse reaches the area near the magnet, a torsional wave is generated.

This wave travels back to a pickup sensor.

The time-of-flight is measured — this gives the exact position of the magnet.

💡 Since the sensor only measures how long the wave takes to return, there's no physical wear, which means high durability.

🏭 Where Are Magnetostrictive Sensors Used?

They’re everywhere — especially in environments where precision and reliability are critical:

🚀 Aerospace: Flap and actuator position sensing

🏗️ Industrial Automation: Position of robotic arms, actuators, or hydraulic pistons

🔧 CNC Machines: Precise feedback for machining

🏥 Medical Equipment: Non-invasive and highly accurate motion sensing

🛢️ Hydraulic Cylinders: Especially in mobile machinery and presses

✅ Advantages of Magnetostrictive Sensors

Feature | Magnetostrictive Sensor | Potentiometer | LVDT | Hall Effect |

Non-contact operation | ✅ | ❌ | ✅ | ✅ |

Durability | ✅ | ❌ | ✅ | ✅ |

Accuracy | ✅ High | Medium | High | Medium |

Environmental Toughness | ✅ | ❌ | ✅ | ❌ |

Cost | Moderate | Low | High | Low |

🛒 Best Magnetostrictive Sensors in 2025

Here are some of the top-rated sensors available for industrial and robotics use:

1. Temposonics E-Series (MTS Sensors)

💡 Reliable, compact, and widely used in automation.

2. Balluff BTL Series

Known for rugged build and flexible output options (analog, SSI, CANbus).

🔗https://www.balluff.com/en-se/products/BTL

3. GEFRAN MK4-A

Great for harsh industrial environments with excellent EMI protection.

🧠 Pro Tip: Use affiliate boxes with images, price ranges, and “Buy Now” buttons.

📘 Buying Guide: How to Choose the Right Magnetostrictive Sensor

When picking a sensor, consider:

Feature | What to Look For |

Stroke Length | Match your machine’s range |

Output Type | Analog (0-10V), SSI, CANbus, etc. |

Housing | Sealed for oil, dust, or water |

Mounting Style | Rod-style, profile-style |

Temperature Range | Industrial settings can be extreme |

🧲 Magnetostrictive vs. Other Sensors: Why They're the Smart Choice

If you’ve been using potentiometers or LVDTs, switching to a magnetostrictive sensor might:

Reduce maintenance

Improve precision

Extend equipment life

Typical Engineering Calculations in Magnetostrictive sensors:

🧠 1. Time-of-Flight (TOF) Calculation

Core principle: The sensor calculates position by measuring the time it takes for a torsional wave to travel from the magnet to the pickup coil.

🧮 Formula:

d = distance from the start of the waveguide to the magnet (m)

v = speed of torsional wave in the waveguide (~3000 m/s for magnetostrictive material)

t = total time of flight measured (s)

The division by 2 accounts for round-trip travel (pulse goes to magnet and returns as a wave).

🔧 Example:

🧠 2. Resolution Calculation

Resolution depends on:

The time measurement resolution of the electronics

Speed of wave in the material

Formula:

Example:

If electronics measure time with 100 MHz clock:

🧠 3. Accuracy & Error Calculation

Common sources of error:

Temperature drift

Electromagnetic interference

Delay in electronics

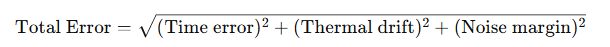

Total error estimation:

For example:

Time error = ±10 µm

Thermal drift = ±5 µm

EMI noise = ±2 µm

🔚 Final Thoughts

Magnetostrictive sensors offer a unique blend of precision, reliability, and robustness. Whether you're upgrading factory automation or fine-tuning a robotic system, they’re an excellent investment.

Comments